Burn the Clipboard? Embracing Digital Water Data Collection

Background

I have been consulting in the water and wastewater IT/OT industrial automation space for about 25 years. Not just as a consultant sitting behind a desk writing reports all day, but I’ve been in hundreds (thousands?) of facilities and have seen a lot of data and the people who steward it in this industry. I had a morning meeting a few years back where a plant superintendent of 20+ years told me the state would never allow him to go without paper, then after lunch, I sat with another superintendent a few miles away that told me he’s been emailing the state a PDF of his monthly operating report for the last 5+ years. I’ve seen some wastewater plants operate totally paperless and other plants in the very same county swear that if they ever had to get rid of paper, they would be in violation of Federal law and might just quit (I’m serious). I’ve actually been threatened by well-intentioned but a bit overly zealous supervisors asking me to “never bring up going paperless again.” Whether you are paperless, light paper, or sleep with your clipboard under your AWWA or WEF pillowcase, one thing that’s consistent in water is the people in this industry value the integrity and responsibility required to capture and manage data of their systems well.

“I’ve actually been threatened by well-intentioned but a bit overly zealous supervisors asking me to ‘never bring up going paperless again.’”

The truth is that water and wastewater utilities across the globe (like many businesses), are being stretched to do more with less resources. We are being asked to find ways to work smarter and make the same resources do more than they previously did for us. And it really doesn’t do much to help by just waiting for the Feds to provide better funding. Technology can really help in a situation like this…if wisely and appropriately applied.

The Clipboard’s Legacy in Water

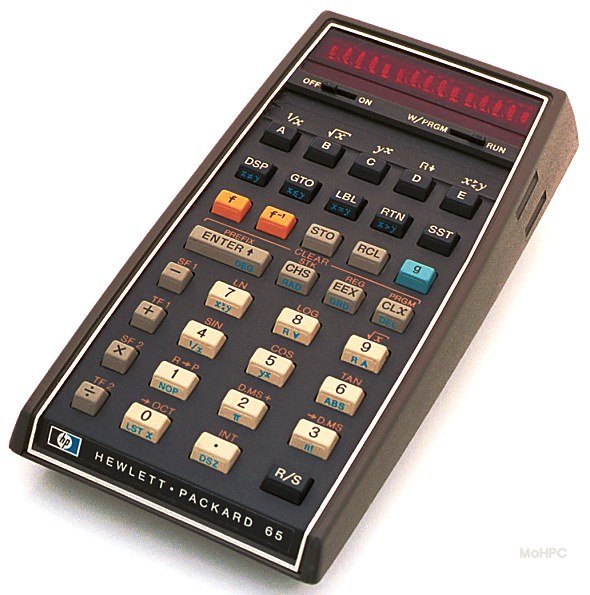

Photo Credit: HP Museum

From what I could research, the clipboard was originally called a “board clip” and was first patented in 1870-71. It was a brilliant invention that helped its users to be able to legibly write “on the go” with one hand while supporting paper with the other hand (more on the “legibly” piece later). Water operators since before the dawn of the Clean Water Act in the early 1970s used clipboards to capture data like pump runtimes, flow meter totalizers, as well as in the lab to measure various water quality parameters. Grab a pencil, a fresh form, and write down what you see. Initial it for validation. Make a mistake? Simply erase and re-enter. Simple is good. In the 1970s, we could just barely use a calculator to add up usage or divide by the number of days to get averages. The light analysis gave us better visibility into the variability of the operational parameters of our water and wastewater systems.

Then came the spreadsheet. At first, it was VisiCalc, then Lotus 1-2-3, then eventually Microsoft Excel and Google Sheets. Spreadsheets were (are still) great, but operators have to sit down at the end of the day, or week, (or month?), and type results into a spreadsheet template, learn how to use formulas, format it for readability, and if they were adventurous, they would plot the results in a trend to aggregate and visualize their data. Double data entry though (clipboard + spreadsheet) every time. Then automated SCADA data came along to lessen the burden of typing into the spreadsheet, but at the end of the year, a town with three water plants would usually end up with 36 spreadsheets, one per month for each plant. Not ideal as you look to find trends across years.

About six or seven years ago, when Waterly was in its “define the problem” phase, we did a lot of talking and visiting with literally hundreds of operators in the Midwest US about how they manage data. To this day, we still ask utilities what method they use to collect and manage operational data. With thousands of data points in more than half the US states surveyed, we can say confidently that over 90% of US water and wastewater utilities (we have onboarded over 700) primarily use a clipboard and spreadsheets to manage their data.

Time for a Change

It’s time water professionals consider a shift to “do more with less” and burn that clipboard. Asking an employee to record data once, on a clipboard, with no feedback, no warnings, no range checking, and little context, is simply poor stewardship of your time as an operator. I’m going to avoid the normal hyperbole of saying it’s terrible or even old-fashioned. I’m old enough to understand that old-fashioned doesn’t mean bad…but I am going to stand by and say it’s poor stewardship of your time. I’m also going to avoid saying that doing rounds is poor stewardship, because I’ve learned that despite the advances in sensors and SCADA, there are times when an operator’s ears, eyes, and nose (yes) looking at…say a dissolved oxygen (DO) meter are more valuable than just knowing that the DO level is 1.81 mg/L, for example. Each facility should decide how useful it is to be in the field capturing data versus looking at your SCADA screen in the control room. I’m just saying that taking the time to write something down, hoping it’s legible, then having someone later (when a dangerous value might have long passed) type it in (again), is time wasted that should be spent mentoring someone or managing your facility…two things a computer or even AI cannot do, nor will ever be able to do, by the way. Aside from being a poor use of time to enter data twice, I offer the following additional reasons why burning the clipboard might be advisable:

Bad Handwriting is Dangerous for Water Quality – As much as we appreciate George Henry Hohnsbeen’s invention to hold the paper solid while we write, numbers can be hard to interpret later. Additionally, penmanship of all operators is not tested during the interview. In an industry where an incorrect interpreted reading or result could mean misrepresented data, a more costly violation, or worse, a negative health impact due to improper settings, we just should not tolerate transcription errors.

You will miss opportunities for in-field education – Having a digital system that can tell you your entered value is out of normal operating range while you are looking at it gives you the opportunity to correct the situation with the instrument or the process. Or maybe you should call a supervisor for advice on how to correct a high or low dosage. Yes, many senior level operators know what ‘normal’ looks like, but many of our industry’s incoming workforce doesn’ t have that wisdom, and may end up “just writing it down.”

Paper Burns – What do I mean? There is no backup to it until another human being scans it or types it in. Many facilities don’t do their data input until the end of the week or even month. During that time, we could lose the paper, stain the paper, or yes…a fire could cause you to entirely lose your work. Additionally, reducing paper demand means less trees have to be milled into paper in the first place.

File Cabinets – Do we really need to keep all this paper? Admittedly, the 1990s brought us enough data disasters in the news to encourage us to make sure we have backups of our data. Trusting your regulatory and operational data to the magnetic or quantum state of electrons in some spinning invention we can’t understand (electronic data storage) is a bit unnerving. However, in today’s information systems, data backups are fully automated (and usually offsite), servers are redundant, power is redundant, and all for a fraction of the cost of a file cabinet.

So if you are considering entering your data into a homegrown spreadsheet directly…

Back it up - Make sure your data is backed up somewhere. Most cloud services such as Microsoft 365 and Google Sheets (and Waterly) should do this for you if set up properly, but make sure that you or your cloud data provider has told you in writing that they have a backup plan.

Have a back-up plan – The Internet and your digital data service won’t be there for you 100% of the time. While most good providers will likely give you better than 99.9% availability, almost no one will promise you 100% uptime. Your Internet may go down. Your phone battery might be dead. The cell provider might have an issue in the area where service is not reliable. At those times, you’ll want to maybe have a bottom drawer in your desk that has some rounds sheets, a trusty pencil, and maybe…that dusty, trusty clipboard.

Concessions and Conclusions

Each state and regulatory body has slightly different rules for record keeping, but we encourage water quality professionals to find them, read them, or call your local regulatory inspector and ask them to point you to them. We have had hundreds of operators and engineers tell us that paper “is required” in their state, when, in reality, there is no requirement for paper. Laws change frequently though and utilities should make sure they understand the reality of what is required versus what they’ve always been told is required.

Water is not best-served by complaining about how we don’t have enough resources to get our job done. Our industry is filled with some of the most gritty, ingenious, creative, and loyal people in the world. By leveraging their wisdom, with the right technology, the pressure to do more with less is reduced along with all the other benefits of the right technology.